From working towards net zero, diverting the amount of waste we send to landfill and increasing the percentage of material we recycle, we are focused on building responsibly.

Our commitment to reaching net zero

We cannot realise this ambition without doing our part to address climate change.

Our pathway to achieving our net zero goal

We have committed to reaching net zero greenhouse gas emissions across our value chain by 2045. This means reducing the emissions produced by our own business operations, as well as the emissions produced through our supply chain and by the homes we build when they are lived in by our customers.

We have set ambitious but realistic near and long-term targets to provide a clear pathway toward achieving our net zero goal. To help ensure we can achieve our ambitions, these targets have been validated by the Science Based Target initiative.

Reaching net zero won't be easy, but it's absolutely crucial – for the planet, our customers, and the resilience and sustainability of our business.

Read more about our validated, science-based targets and the actions we are taking in our Environmental Sustainability Strategy. Environmental Sustainability Strategy 2024

Towards net zero

Climate scientists have set out a need to significantly reduce greenhouse gas emissions by 2030 if we are to have an orderly transition to reaching net zero emissions by 2050.

Short-term Carbon Reduction

The Science Based Targets Initiative officially approved our targets in September 2024.

Our short-term commitment will be to deliver a 50.4% reduction in carbon emissions by 2032, against our baseline year of 2022. This is a challenging target which needs decisive and determined action over the next few years to set us on course to reach our 2032 target.

How we do it

A number of projects are already underway to help us reach our target. They include solar technology trials, the use of hybrid generators on our development sites, and increasing the supply of renewable electricity across our operations.

Other projects such as reducing machinery idling on sites, solar-backed sales facilities, and increasing our use of electric vehicles are also being considered.

A major step on the journey will be introducing Hydrotreated Vegetable Oil (HVO) fuel as a replacement for diesel. Accelerating site connections to the grid will also be required to significantly reduce the need for on-site generators.

How it is measured

We measure our progress through our absolute reduction in tonnes of carbon equivalent, or TCO2e. We also track our emissions against build area and number of homes completed each year. This allows like-for-like comparisons to be made across businesses and sectors and helps us keep track of how efficiently we operate.

Commitment to Net Zero - Scope 3

We are committed to reaching Net Zero carbon emissions by 2045. To achieve this goal, we need to address emissions across the entire supply chain, including Scope 3 or ‘indirect’ emissions.

Scope 3 emissions are usually much larger in scale than Scope 1 and 2 emissions. The design of our homes, the heating fuel used, and how our homes are used by customers after they move in has a significant impact on Scope 3.

However, if the UK’s electrical supply continues to decarbonise, then the impact of carbon emissions from our supply chain will become most significant.

This is particularly true for ‘energy intensive’ materials which need a lot of energy to produce, such as bricks, cement and roof tiles. Waste generation, business travel and commuting also contribute this group of emissions.

How we do it

We have assessed our Scope 3 emissions and developed a roadmap to deliver significant short-term carbon reductions. Reaching Net Zero in 2045 will build on this roadmap.

Critical actions will include designing our homes in line with the new building regulation requirements for carbon reduction in England and Scotland.

The current Part L regulations in England will deliver a reduction in carbon emissions of around 31%, and from 2025 the Future Homes Standard will drive this improvement up to at least 75%. Homes built under the Future Homes Standard will be ‘Net Zero’ ready, able to run wholly on clean energy, and reaching zero emissions when the electricity grid is fully decarbonised.

We will also consider how different materials could help us reduce the carbon emissions created from the manufacture of construction materials. We will work with our supply chain to understand how their own carbon reduction plans can support our sector to reduce what is known as embedded carbon.

We are already taking action to reduce waste in our business and have started transitioning our company car fleet to fully electric and hybrid electric vehicles.

How it is measured

Measuring Scope 3 emissions is a complex and iterative process which follows recognised standards for carbon accounting and reporting.

Our energy, materials, cost, waste, services and travel data for a given annual period is collated. Carbon factors are applied to each element to create a carbon footprint for the entire value chain of our business.

Reducing waste

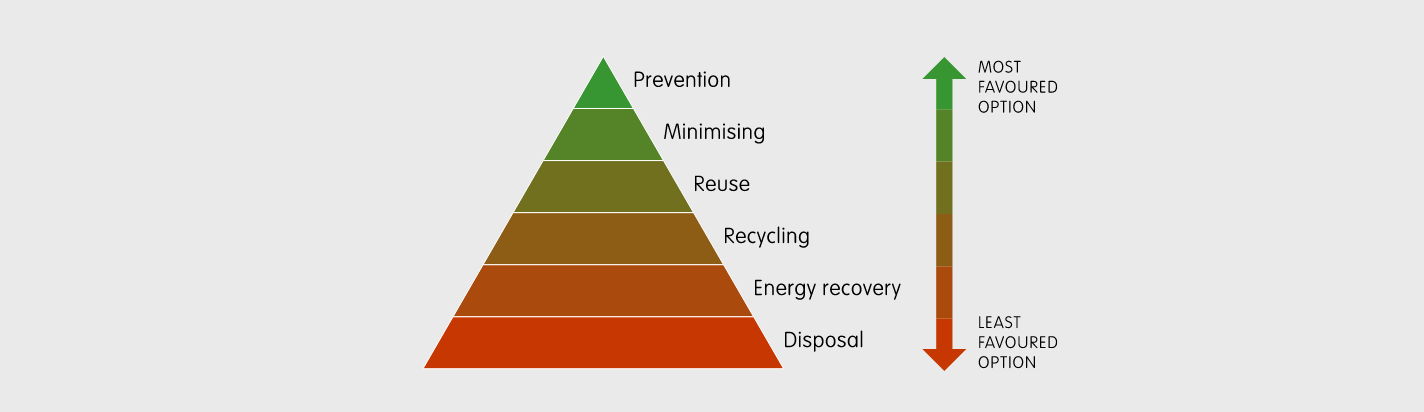

Billions of tonnes of resources are extracted annually causing damage to the environment and resulting in huge volumes of carbon emissions. Many of these resources ultimately end up as waste. We are focused on reducing our use of raw materials, increasing recycling rates and avoiding incineration and landfill of unwanted materials.

98% diversion from landfill by 2025

We have been working with our waste partners for a number of years to divert 98% of our waste from landfill and into recycling or recovery processes.

How we do it

Diversion rates across our regions are driven by on-site controls and segregation, and working with waste contractors who can recover high levels of waste materials through their processes.

How it is measured

Our diversion of waste from landfill is measured through reports supplied by our waste contractors which split out waste sent to landfill, for recovery, recycling and reuse by material type and site.

75% recycling rate across group by 2025

Reducing the use of raw materials is essential. One way to do this is to recycle waste materials back into new ones, ideally the same raw material which can then be used again.

83%

In 2023, we sent 83% of our waste to recycling processes through our waste service providers.

How we do it

Analysis of recycling rates across current suppliers has highlighted those waste contractors who can already deliver good recycling rates and those that will require improvement. By working with our waste partners, we aim to place more waste with the best performing processors in the sector.

How it is measured

We use a reporting template for our waste contractors to ensure we can accurately and easily track our recycling rate.

In 2023 we sent 83% of our waste to recycling processes through our waste service providers.

Reduction of waste per plot

In 2024 we launched a major initiative to reduce waste per plot. Preventing waste in the first instance is the most effective way to protect the environment from over consumption of resources and the impacts of dealing with waste.

How we do it

Our Tackling Waste for A Better Place project focuses on reuse of materials such as hardcore on site, and ensuring that reusable waste streams, such as pallets, are returned to suppliers.

We are exploring more opportunities to prevent waste arising on site, including pre-cutting materials such as plasterboard and flooring.

How it is measured

Our waste contractors provide reports with data on total tonnes of waste produced at each site. We divide these volumes by monthly production numbers to derive a waste per plot number for sites, regions and the Miller Homes business as a whole.

Our site teams have targets to reduce the waste per plot produced. In 2024, engagement with our sites and our waste service suppliers has started to drive down the amount of waste disposed of.